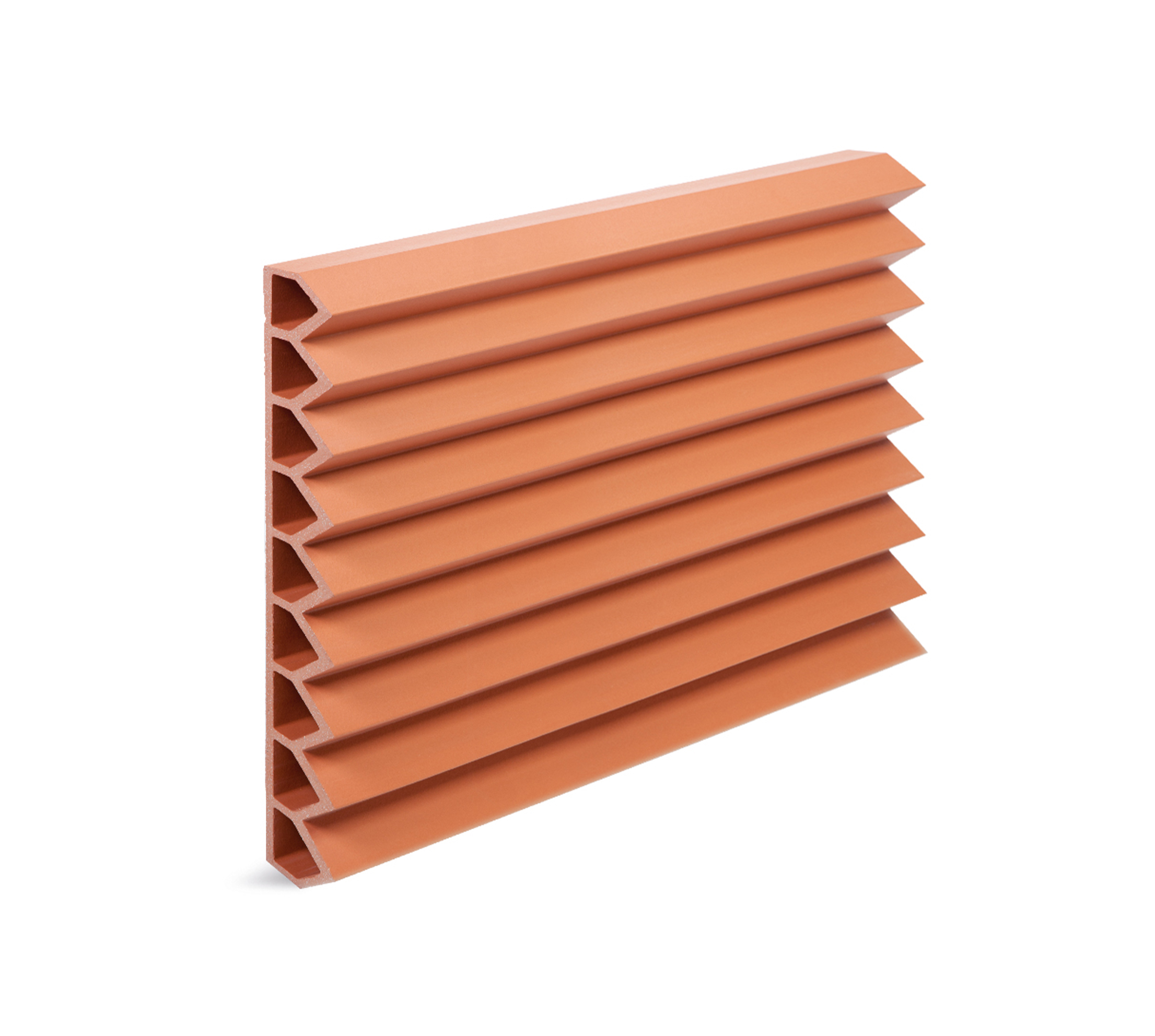

FK PIECES

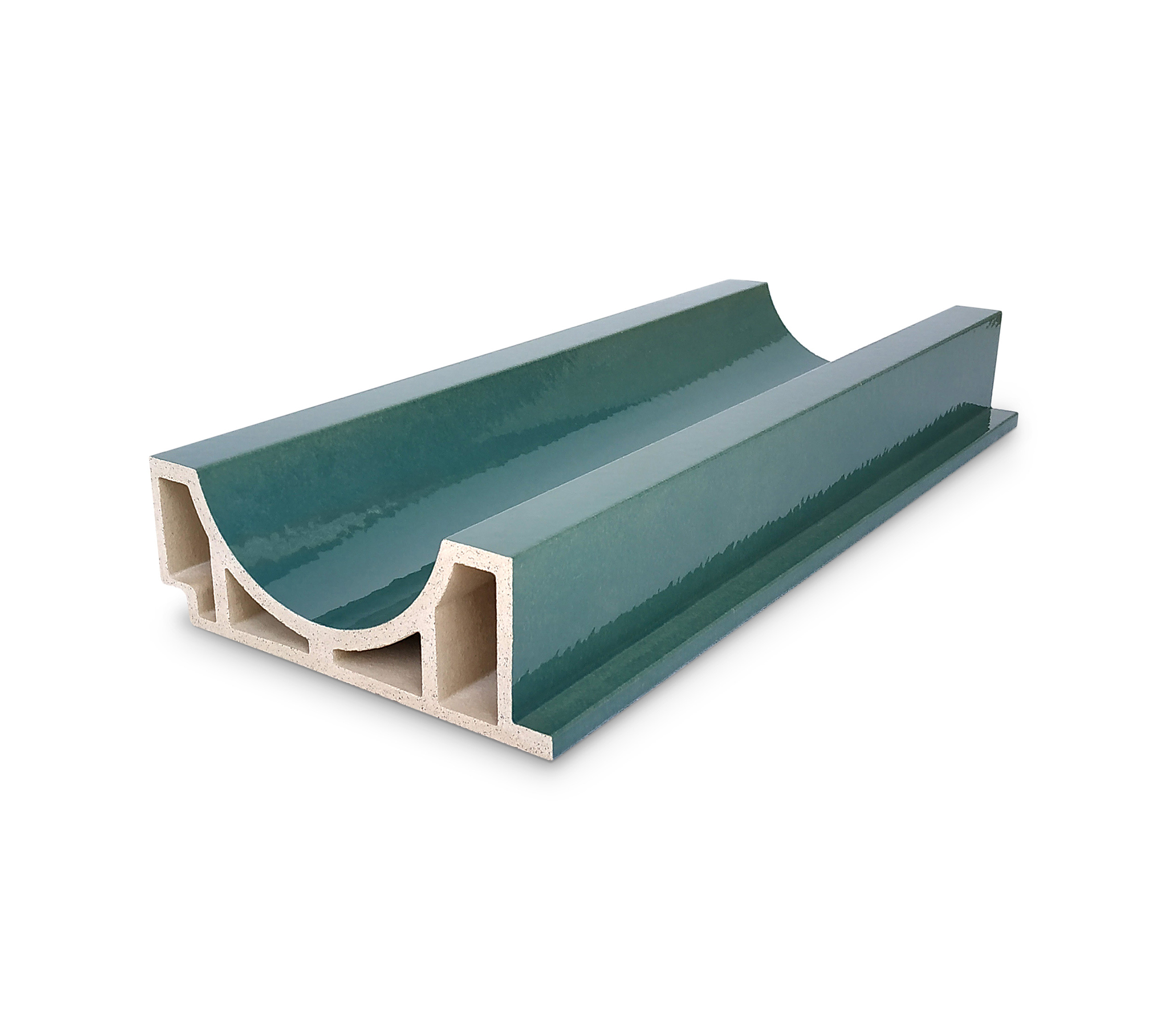

FS PIECES

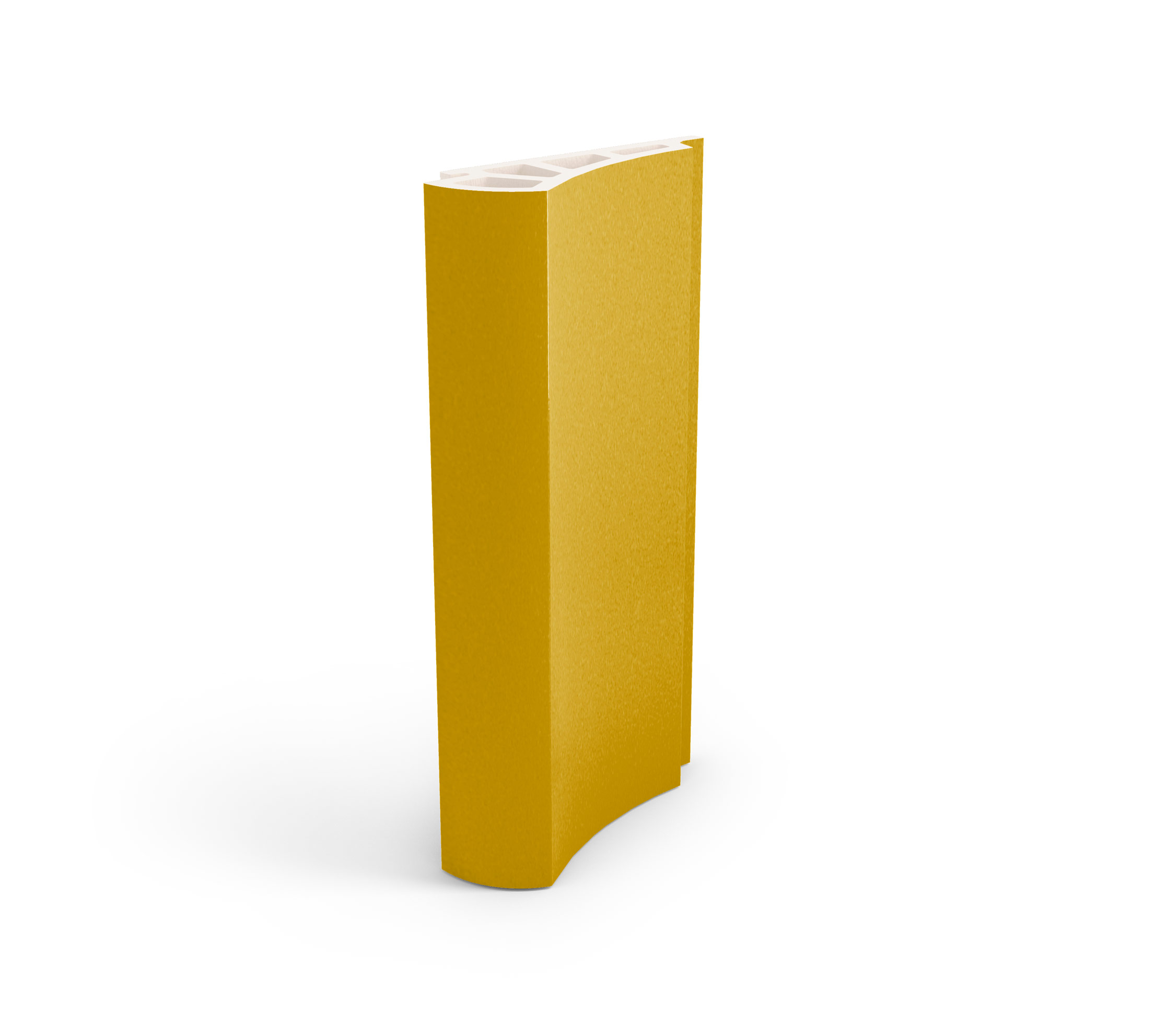

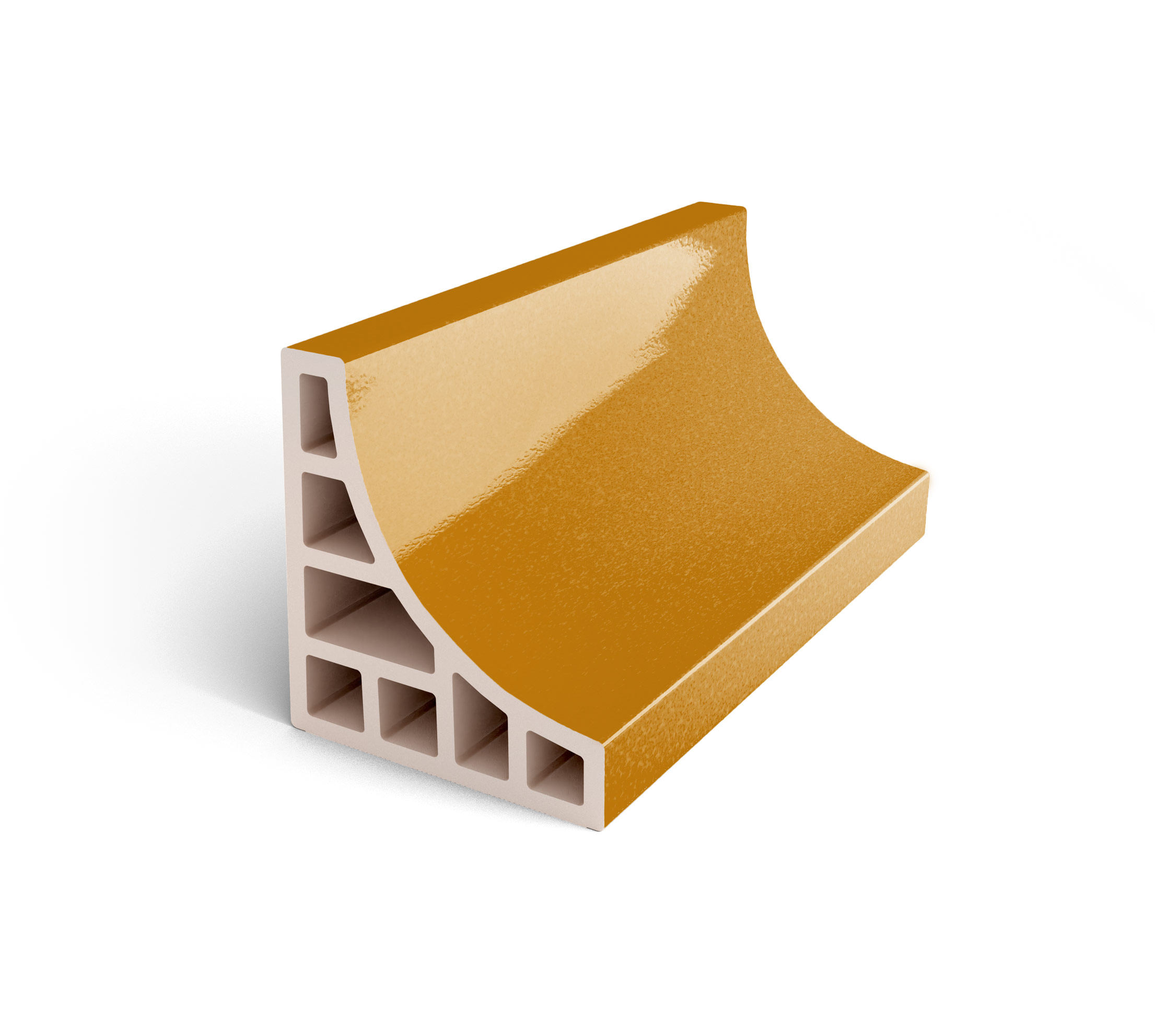

HIGH PROFILE

BAGUETTE

LISTELOS

RUSTIKOTTA

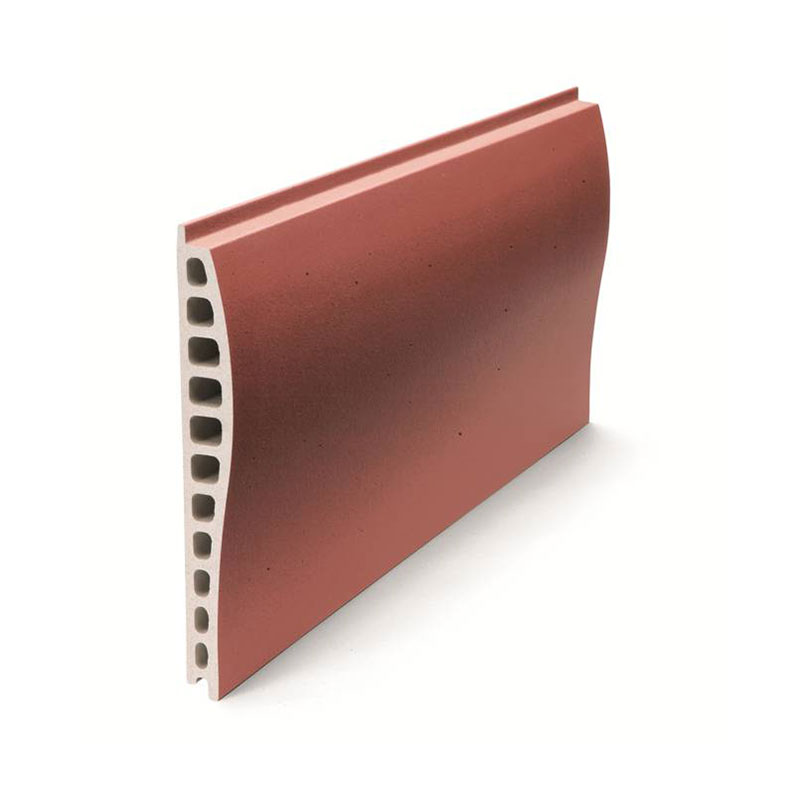

FK SYSTEM

This system has open vertical and overlapping horizontal joints. Composed of brackets, vertical T profile, horizontal rails and metallic springs which have an anti-ratling function. When installing it, we will constantly check weights and levels. We fix the brackets to the slab with a mechanical anchor and we fix the bracket to the wall using a chemical/mechanical anchor. The anchors will be the most suitable according to the quality of the wall. We fix the vertical profile to the brackets with self-drilling steel screws. This union should allow the elongation of the vertical profile. In order to achieve this, we rivet a fixed point in the above bracket and we rivet the following brackets with mobile points. This pattern is used to place the entire horizontal profile. If, for example, we start right to left, we would fix the first on the right and the following would be mobile. We will always follow this guideline throughout the building’s entire vertical line. Then, the fixing of the pieces or cladding to the facade is carried out including the use of means of a steel spring, .Light alveolar piece of 16/20 mm thick, with double anchorage on the rear part that prevents the piece from coming loose in any situation. The open joints improve the ventilation of the facade. The main advantages of this model are that it is easy to install and is very light, only 28 kg/m2. This makes it a light, cost-efficient and reliable system.

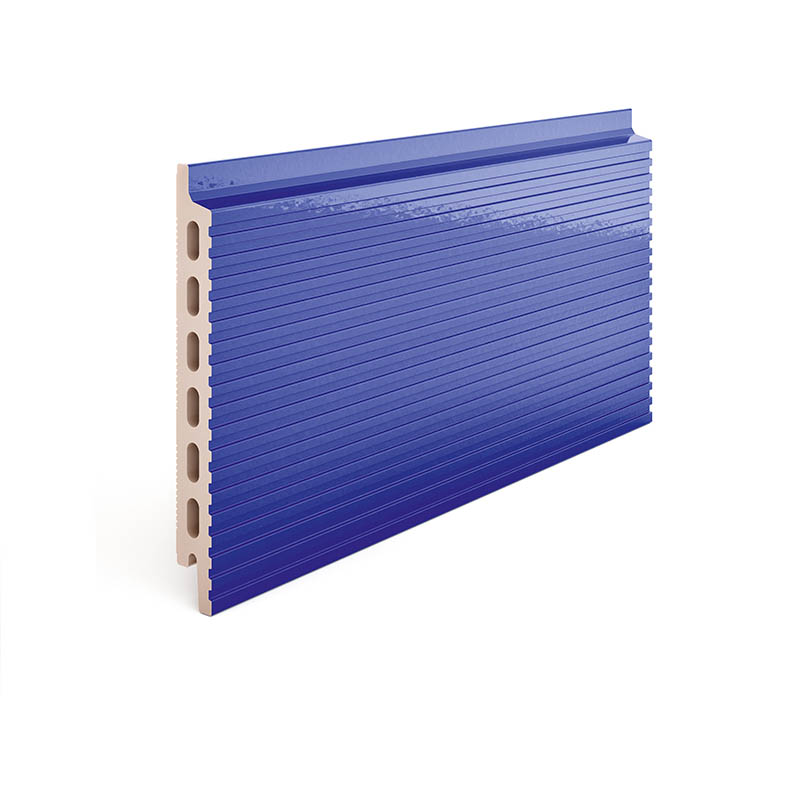

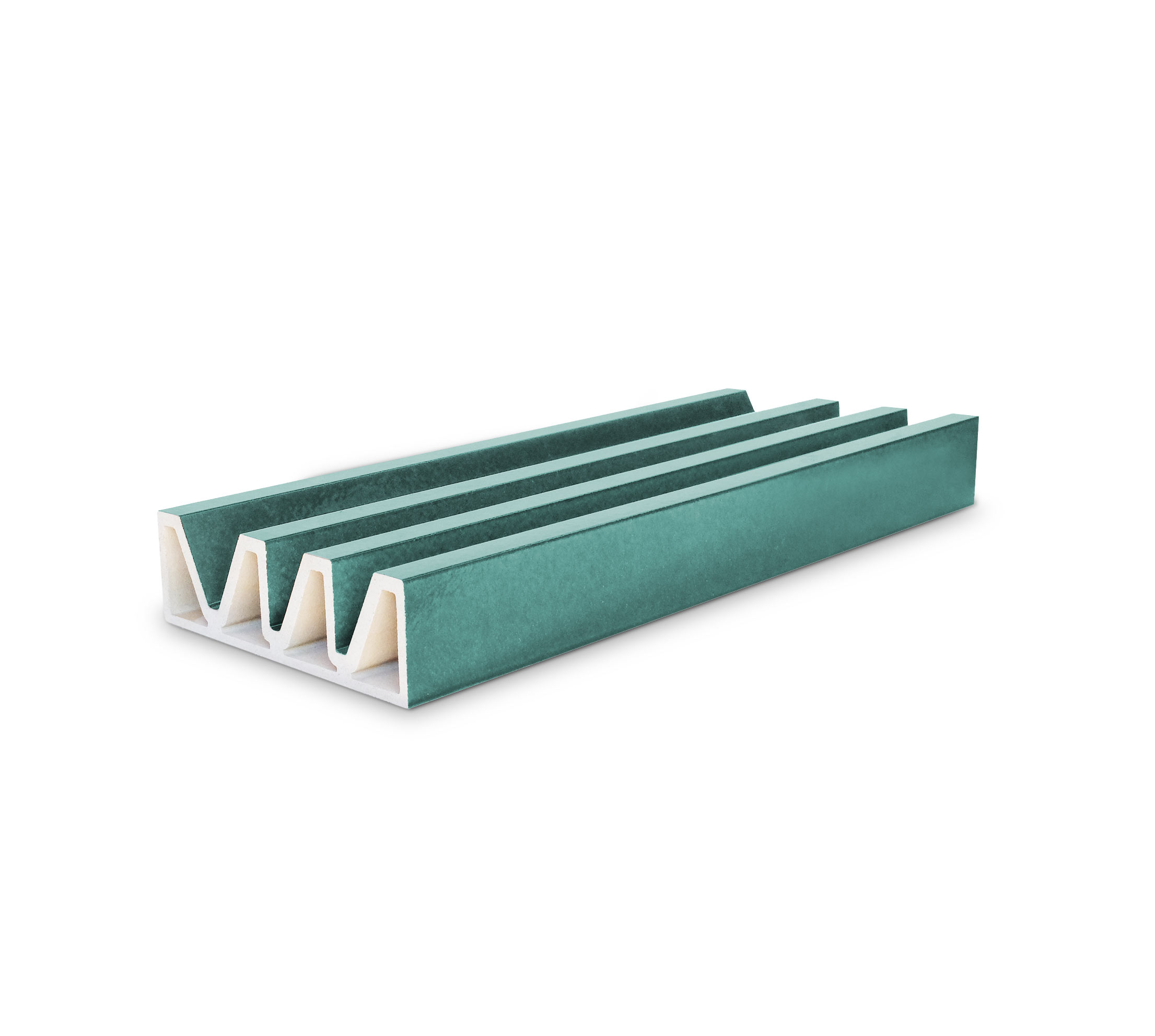

FS SYSTEM

This system has open vertical and overlapping horizontal joints. Alveolar piece system that we designed with the needs of the international market in mind. It is an innovative system of vertical and horizontal overlapping joints that prevents rainwater from entering. Its thickness provides a great resistance to impacts. It is easy to replace the pieces and practical to hide installations.Its placing, with a wider perpend, fairly marks the horizontality of the pieces. This system has a special aluminium clamp that holds the piece and links it to the structure. When installing it, we will constantly check weights and levels. We fix the brackets to the structure with a mechanical anchor, and to the wall using a chemical anchor. The anchors will be the most suitable according to the quality of the wall. We fix the vertical profile to the brackets with steel rivets, so it allows the dilation of the aluminium. To do this, we rivet a fixed point above and the following with mobile points. Always following the same installation pattern, if, for example, we start right to left, we would fix the first on the right and the following would be mobile. We will always follow this guideline throughout the building’s entire vertical line. A laminated aluminium spring completes the structure, which closes the vertical joint and absorbs the vibrations introduced by external agents. Once the structure is finished, the pieces will be placed with the aluminium clamps.

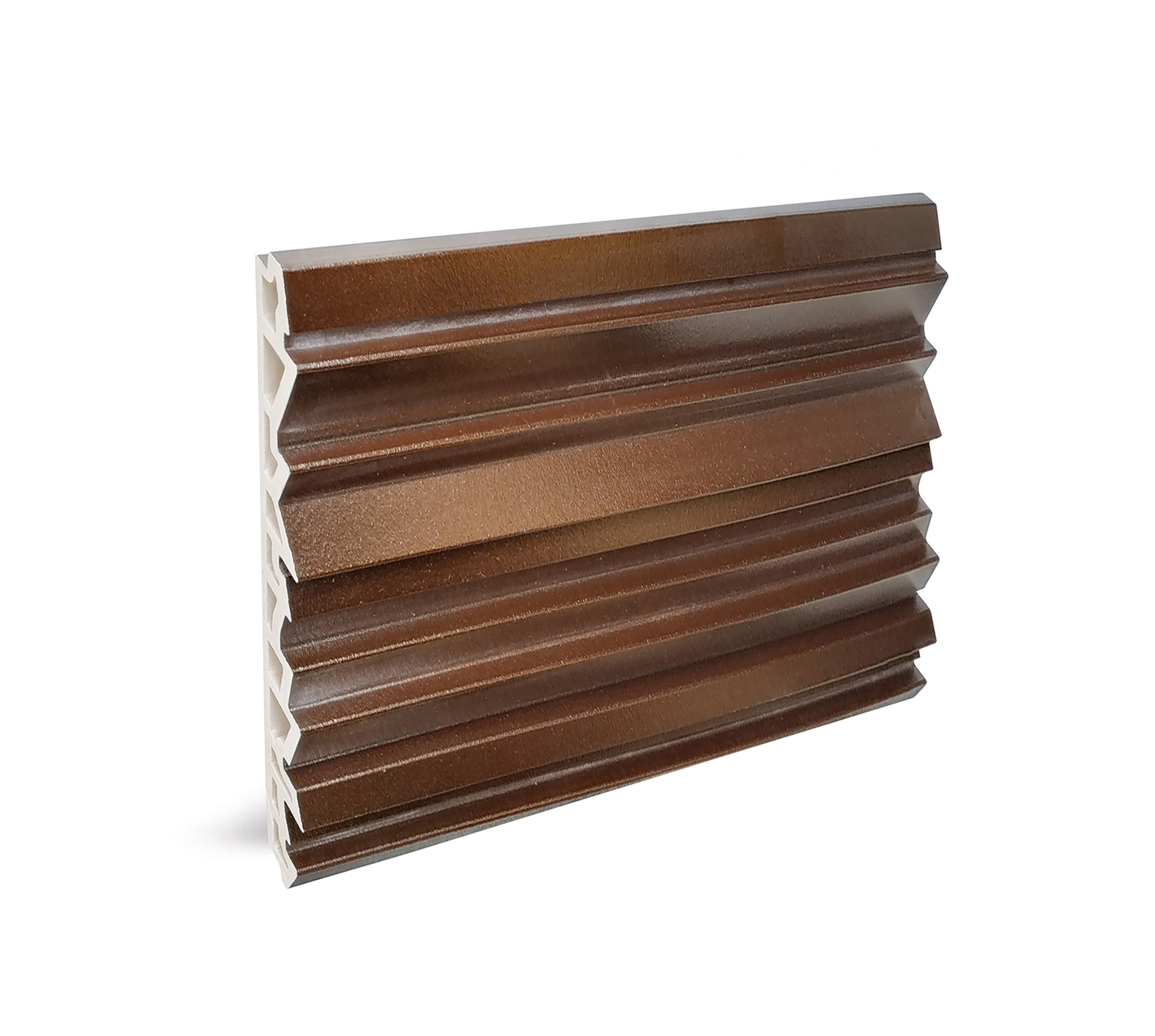

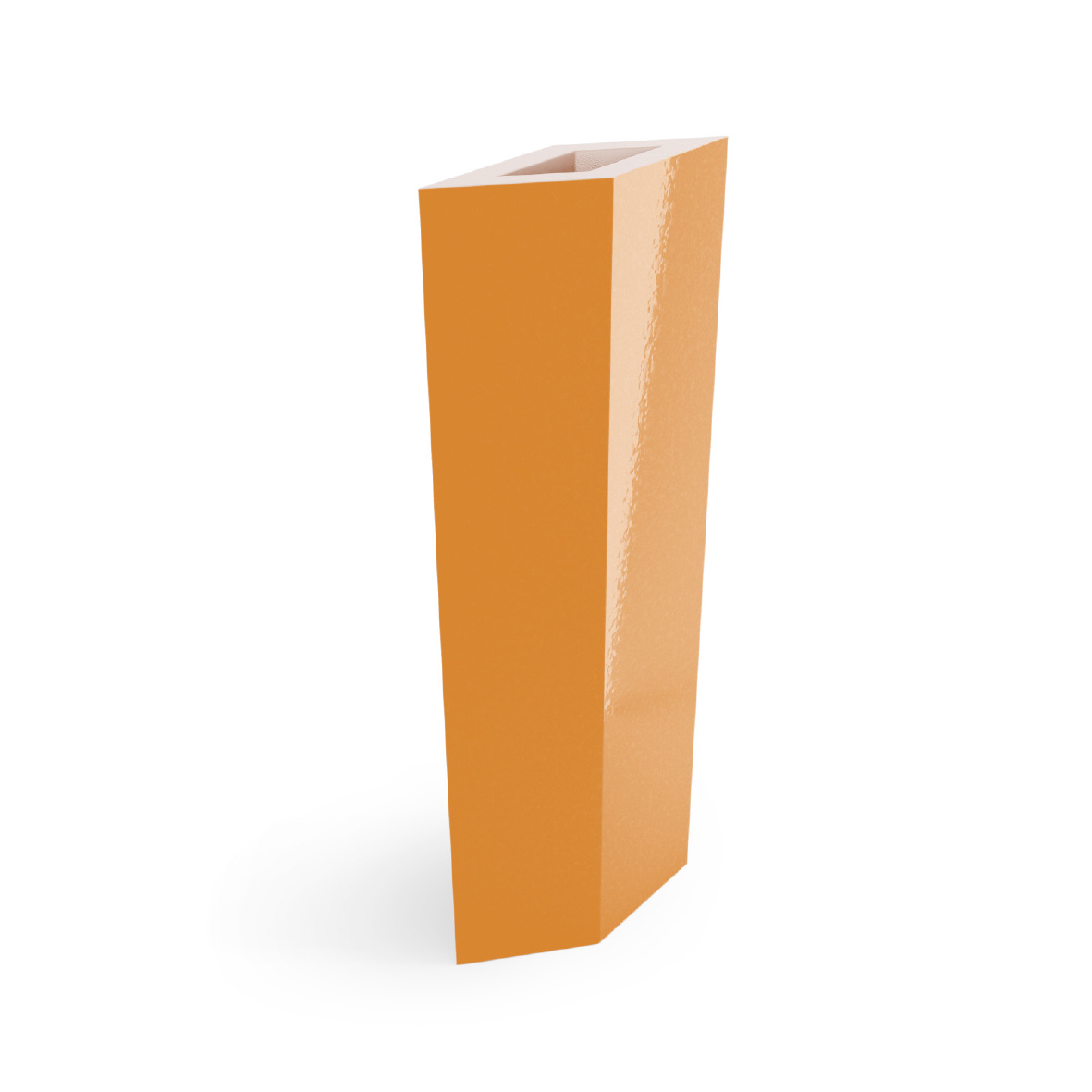

HIGH PROFILE PIECES

This group covers the pieces which have been designed for a specific project and the pieces which have a different anchoring system. These pieces could arise from two differnt facts: the close collaboration between TEMPIO and the architure team of one specific project or the own Tempio concerns as ceramic manufacturers.